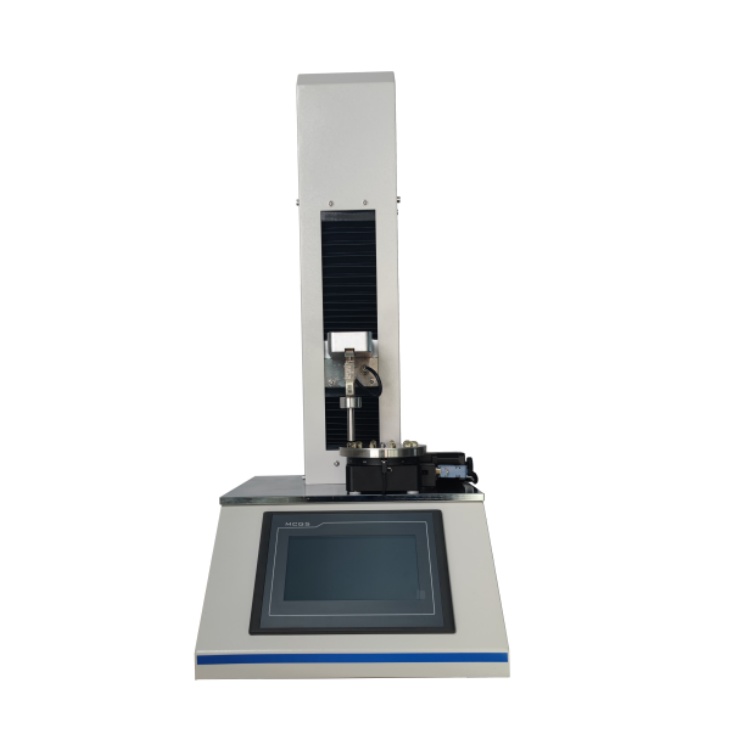

FSR-01 Shrink Force and Ratio Tester

The FSR-01 Shrink Force and Ratio Tester is a state-of-the-art instrument designed for accurately measuring both the shrink forces and shrinkage ratios of heat shrinkable films. These films, which undergo extrusion and stretching (hot drawing) during their manufacturing process, maintain their stretched state even after cooling. When reheated to the temperature where the initial stress was introduced and subsequently fixed, the stress is released, causing the film to contract or "shrink back." The film can be categorized as either biaxially oriented (stretched in two directions) or uniaxially oriented (stretched in one direction) based on the specific manufacturing treatment applied.

Testing Process

- Heating the Air Oven: The well-insulated air oven is heated to a precise set temperature. Two samples are placed separately on two test stations for shrinkage rate and shrink/contraction force testing.

- Temperature Probe Measurement: A temperature probe located in the measuring area provides accurate reference temperatures. The air oven automatically covers the sample area, ensuring controlled testing conditions.

- Force and Shrink Rate Measurement: The force and shrink rate are measured as the shrinkage temperature is reached when the maximum shrinking force is attained. The oven is lifted once the force decreases by 15-30%, and time is recorded.

- Shrinkage Ratio Assessment: The assessment of the shrinkage ratio is performed at the mean time, ensuring precise evaluation of film properties.

- PLC Control and HMI Touch Screen: Ensures industrial-level stability and user-friendly operation.

- Well-Insulated Air Oven: The air oven is excellently insulated, capable of automatic lowering and lifting, which enhances testing precision.

- Non-Contact Shrink Ratio Measurement: Achieved through a non-contact method, improving accuracy and reliability.

- Real-Time Display: Displays shrinking force, contracting force, and shrinkage ratio, allowing for immediate analysis and monitoring.

- Elimination of Interference Factors: Effectively eliminates irrelevant interference factors like friction and cool air, ensuring the accuracy of results.

- Stable Heating System: The heating system is stable and well-balanced, maintaining consistent and controlled test conditions.

- Easy Sample Loading: Simplifies sample loading, streamlining the testing process and reducing setup time.

- High-Resolution Sensors: Equipped with high-resolution force transducers and thermometers, guaranteeing precise measurements.

- Connectivity and Software: Includes an RS232 port for data connectivity and offers optional professional software for advanced data analysis and reporting capabilities.

The FSR-01 Shrink Force and Ratio Tester is essential for laboratories in industries such as packaging, food, medicine, beverage, and academic research. Its advanced features ensure accurate, reliable, and repeatable measurements, critical for quality control and material research.

| Item | Parameters |

| Force Range | 5 N ( or as required) |

| Accuracy | ±0.5% |

| Resolution | 0.001N |

| Displacement Range | 0.1 ~ 95 mm |

| Accuracy | ±0.1 mm |

| Temperature Range | Ambient ~ 210°C |

| Accuracy | ±0.5°C |

| No. of Specimens | 2 |

| Sample size | 110*15 mm, L*W |

| Power Supply | 220V 50Hz |

The FSR-01 Shrink Force and Ratio Tester offers unmatched precision and reliability in testing shrinkable films. With its advanced technology, user-friendly interface, and robust design, it is an indispensable tool for any laboratory focused on material testing and quality control.

ISO 14616, DIN 53369

-

ꄶ By Tester Name

-

Leak Tester

-

Pressure Decay/Burst Tester

-

Micro Leak Tester

-

Gross Leak Tester

-

Tensile Tester

-

Heat Seal Tester

-

Coefficient of Friction Tester

-

Falling Dart Impact Tester

-

Falling Ball Impact Tester

-

Pendulum Impact Tester

-

Hot Tack Tester

-

Shrink Tester

-

Cling Peel Force Tester

-

Thickness Tester

-

Flex Durability Tester

-

Elmendorf Tear Tester

-

Peel Test Stand

-

Test Stand

-

Impact Tester

-

Carbonation Tester

-

Torque Tester

-

Bottle Tester

-

Lid Film Peeling Tester

-

Box Compression Tester/BCT Tester

-

Ink Rub Tester

-

Mullen Bursting Tester

-

Plybond Tester

-

Stiffness Tester

-

Folding Endurance Tester

-

Beating Freeness Tester

-

COBB Tester

-

Concora Medium Fluter

-

Puncture Tester

-

Crush Tester

-

Ink Rub Tester

-

Paper Core Compression Tester

-

Paper Dirt Tester

-

Board Thickness Tester

-

Paper Thickness Tester

-

Softness Tester

-

Short Span Compression Tester

-

Paper Tear Tester

-

Smoothness Tester

-

Air Permeance Tester

-

Paper Tensile Tester

-

Valley Beater

-

Bending Stiffness Tester

-

Taber Stiffness Tester

-

Ampoule Breaking Tester

-

Softgel Hardness Tester

-

Pharm and Medical Packaging Tester

-

Glass Grain Sampling Machine

-

Cap Opening Force Tester

-

Medical Syringe Tester

-

Puncture Tester

-

Drawing Volume Tester

-

Tablet Hardness Tester

-

Motorized Torque Tester

-

Package Compression Tester

-

Verticality Tester

-

Bottle Thickness Tester

-

Top Load Tester

-

Vibration Test Machine

-

Ball Tack Tester

-

High Speed Unwinding Force Tester

-

Loop Tack Tester

-

Tape Shear Adhesion Tester

-

Cleaning Efficacy Tester

-

Mop Cloth Coefficient of Friction Tester

-

Hot Air Thermal Shrinkage Tester

-

Mop Friction Force Tester

-

Charpy and lzod lmpact Tester

-

Melt Flow Rate Tester

-

Stylus Pen Sliding and COF Tester

-

Pendulum Hammer Striking Tester

-

Texture Analyzer

-

Gel Strength Tester

-

Tensile Tester

-

Needle Penetration Tester

-

Needle Toughness Tester

-

Syringe Leak Tester

-

Syringe Positive Pressure Tightness Test

-

Needle Tube Stiffness Tester

-

Syringe Sliding Resistance Tester

-

Needle Toughness Tester

-

-

ꄶ By Test Type

-

ꄶ By Test Material

-

ꄶ By Industry

-

ꄶ By Test Standard

-

ꁇ GB Standard

-

GB 8808

-

GB 7000.1

-

GB 10006

-

GB 15171

-

GB/T 10792

-

GB/T 1040

-

GB/T 9639

-

GB/T 8809

-

GB/T 13519

-

GB/T 6672

-

GB/T 451

-

GB/T 6547

-

GB/T 10440

-

GB/T 18454

-

GB/T 19741

-

GB/T 17447

-

GB/T 17876

-

GB/T 10004

-

GB/T 40266

-

GB/T 2637

-

GB/T 12416.2

-

GB/T 6582

-

GB/T 15267

-

GB/T 16578.2

-

GB/T 55

-

GB/T 2423

-

GB/T 20138

-

GB/T17876

-

GB/T 8942

-

GB/T 2679.10

-

GB/T12914

-

GB/T 24328.3

-

GB/T 24328.4

-

GB/T 24328.5

-

GB/T24325

-

GB/T 2679.3

-

GB/T 22364

-

GB/T 2679.8

-

GB/T 6546

-

GB/T 6548

-

GB/T 22874

-

GB 2679.6

-

GB/T 4857.3

-

GB/T 4857.4

-

GB 4857.7

-

GB/T 4852

-

GT/T 4851

-

GB/T 3682.1

-

GB/T 3682.2

-

GB/T18742

-

GB/T 18457

-

GB 15811

-

GB 15810

-

-

ꁇ ISO Standard

-

ISO 8295

-

ISO 11607

-

ISO 7765

-

ISO 4593

-

ISO 3034

-

ISO 534

-

ISO 719 ISO 720

-

ISO 12625

-

ISO 6383

-

ISO 1974

-

ISO 16260

-

ISO 9895

-

ISO 1924-1

-

ISO 1924-2

-

ISO 1924-3

-

ISO 12625-4

-

ISO 12625-5

-

ISO 5264

-

ISO 2493-2

-

ISO 12192

-

ISO 3037

-

ISO 3035

-

ISO 16945

-

ISO 2234

-

ISO 12048

-

ISO 2874

-

ISO 2872

-

ISO 8113

-

ISO 2247

-

ISO 1133-2

-

ISO 1133-1

-

ISO 8510-2

-

ISO 14616

-

ISO 37

-

ISO 1926

-

ISO 9626

-

ISO 7864

-

ISO 7886-1

-

-

ꁇ ASTM Standard

-

ASTM D202

-

ASTM D882

-

ASTM D3078

-

ASTM D4918

-

ASTM F1140

-

ASTM F2029

-

ASTM F2054

-

ASTM D1709

-

ASTM D3420

-

ASTM D2732

-

ASTM D374

-

ASTM D1777

-

ASTM F392

-

ASTM D 2063

-

ASTM D3198

-

ASTM D3474

-

ASTM D5264

-

ASTM D5458

-

ASTM D1894

-

ASTM F2338

-

ASTM D1424

-

ASTM D689

-

ASTM F2096

-

ASTM 0000

-

ASTM D2923

-

ASTM D6828

-

ASTM D5342

-

ASTM D5650

-

ASTM D3301

-

ISO 7263-1

-

ASTM D642

-

ASTM D4169

-

ASTM D2659

-

ASTM D4577

-

ASTM D999

-

ASTM D3121

-

ASTM D1000

-

ASTM D3654

-

ASTM D1238

-

ASTM D4917

-

ASTM D3330

-

ASTM F1921

-

ASTM D1922

-

ASTM D638

-

ASTM E4

-

ASTM F904

-

ASTM F88

-

ASTM D1938

-

-

ꁇ YBB Standard

-

ꁇ QB/T Standard

-

ꁇ YY/T Standard

-

ꁇ BB Standard

-

ꁇ TAPPI Standard

-

ꁇ IEC Standard

-

ꁇ JIS Standard

-

ꁇ EN DIN Standard

-

ꁇ PSTC Standard

-

FINAT Standard

-

ꁇ BS Standard

-

ꁇ NF Standard

-

ꁇ GB/T

-